German workmanship - reliable - art of engineering!

Welcome to our traditional company, Halbach & Keplin!

One company, one family, one principle

The company is based on typical German thinking - a primary aim and a traditional basic attitude: sophisticated brand quality for a reasonable price, tailored to the customer and 100% made in Germany!

HKR tools are German brand products. They pass challenges and all tests and prove their high quality through daily use in the industry, craft work and in the consumer sector.

Today, as was the case 60 years ago, our tools are characterised by quality and durability

> mechanical/thermal functionality and resistance

> secure handling

> reliability in everyday use and

> durable value in daily, professional use.

High-quality plastics, 2K, GRP, CRP, zinc tempering grey iron casting with ceramic components Profound knowledge of processes and a modern machine park ensure fast, fault-free processes, also in the individual system components and module sectors. Customer-tailored colour-material components, coating and labelling ensure a directly available end product or personal tool that conquer the market under your brand.

You are then holding a true piece of

"German workmanship" in your hands! - an indestructible original!

Developed for the user’s needs

We take the time to listen.

An important components of a good final result is

> comprehension of the parameters of use

> the complexity of use

> individual requirements

> requirements regarding design, packaging and storage availability.

All cases are special cases - consistent quality is our standard! We will personally provide support and can thus respond directly to your requirements, since we are flexible enough to adapt to the customer's needs and large enough to also implement large quantities and special requirements.

New development - engineer - design - construction Your ideas, brand and business orientation will guide the way. In our experience, the best and quickest solution is to bring everyone to the table. According to your needs, these are:

> you - the customer and decision-maker - with your profile of requirements

> us - the producer - providing fast evaluation and calculation

> an industry designer and CAD constructor, who converts ideas and plans, as well as generating images and samples, and

> of course, a factory representative, who can assess the "feasibility" and possible problems in implementation.

This way, the target is reached quickly and safely, without diversions!

Constructive thinking and implementation!

If our standard product range is not suitable, we will develop, construct and produce a new tool according to your requirements.

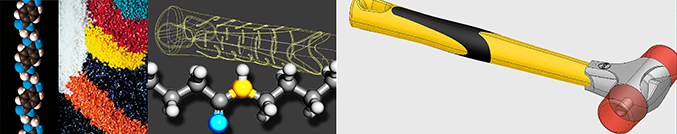

Today, CAD constructions are not only an important element of the new die-cast tools, in fact they provide a real image of the new design project in advance.

FEM calculation simulates an advanced indication of strain for new components, preventing the necessity of important tests and misinterpretations.

In the end, fast process, correct material calculation and assured visual effect are shown - that would otherwise not be seen until the first sample. The completed data is then promptly fed into the 3D printer. Immediately you can experience a full size prototype and gain a haptic impression of the new product.

Construction completed - tool completed - time for pilot production!

We make no secret of the fact that our machine park is completely equipped with machines by the German, quality machine builder “Arburg”.

Hybrid, electrical and vertical die-casting machines produce highly precise injection-moulded pieces in batch production and mass production.

2K, 3K, fibreglass, cellulose acetate, nylon. ... Your wish is our command!

Welcome to our traditional company, Halbach & Keplin!

One company, one family, one principle

The company is based on typical German thinking - a primary aim and a traditional basic attitude: sophisticated brand quality for a reasonable price, tailored to the customer and 100% made in Germany!

HKR tools are German brand products. They pass challenges and all tests and prove their high quality through daily use in the industry, craft work and in the consumer sector.

Today, as was the case 60 years ago, our tools are characterised by quality and durability

> mechanical/thermal functionality and resistance

> secure handling

> reliability in everyday use and

> durable value in daily, professional use.

High-quality plastics, 2K, GRP, CRP, zinc tempering grey iron casting with ceramic components Profound knowledge of processes and a modern machine park ensure fast, fault-free processes, also in the individual system components and module sectors. Customer-tailored colour-material components, coating and labelling ensure a directly available end product or personal tool that conquer the market under your brand.

You are then holding a true piece of

"German workmanship" in your hands! - an indestructible original!

Developed for the user’s needs

We take the time to listen.

An important components of a good final result is

> comprehension of the parameters of use

> the complexity of use

> individual requirements

> requirements regarding design, packaging and storage availability.

All cases are special cases - consistent quality is our standard! We will personally provide support and can thus respond directly to your requirements, since we are flexible enough to adapt to the customer's needs and large enough to also implement large quantities and special requirements.

New development - engineer - design - construction Your ideas, brand and business orientation will guide the way. In our experience, the best and quickest solution is to bring everyone to the table. According to your needs, these are:

> you - the customer and decision-maker - with your profile of requirements

> us - the producer - providing fast evaluation and calculation

> an industry designer and CAD constructor, who converts ideas and plans, as well as generating images and samples, and

> of course, a factory representative, who can assess the "feasibility" and possible problems in implementation.

This way, the target is reached quickly and safely, without diversions!

Constructive thinking and implementation!

If our standard product range is not suitable, we will develop, construct and produce a new tool according to your requirements.

Today, CAD constructions are not only an important element of the new die-cast tools, in fact they provide a real image of the new design project in advance.

FEM calculation simulates an advanced indication of strain for new components, preventing the necessity of important tests and misinterpretations.

In the end, fast process, correct material calculation and assured visual effect are shown - that would otherwise not be seen until the first sample. The completed data is then promptly fed into the 3D printer. Immediately you can experience a full size prototype and gain a haptic impression of the new product.

Construction completed - tool completed - time for pilot production!

We make no secret of the fact that our machine park is completely equipped with machines by the German, quality machine builder “Arburg”.

Hybrid, electrical and vertical die-casting machines produce highly precise injection-moulded pieces in batch production and mass production.

2K, 3K, fibreglass, cellulose acetate, nylon. ... Your wish is our command!

PRODUCT DESIGN

PLASTIC INJECTION MOULDING

MULTI-COMPONEND TECHNOLOGY

PRINTING COMPONENTS

COMPLETELY PACKAGED PRODUCTS

PLASTIC INJECTION MOULDING

MULTI-COMPONEND TECHNOLOGY

PRINTING COMPONENTS

COMPLETELY PACKAGED PRODUCTS

Communication

| ^ 00 49 (0) 2191 / 57 48 | ^ Request / Contact | ^ Privacy | ^ Imprint | ^ Agents | |

| ^ info@hkr-werkzeuge.de | ^ MoS‘#DE 1.17 © all rights reserved: Trademarks, Logo, Designs | ||||

1

1 2

2 3

3 4

4